Benefits

Fuel economy, efficiency, emission!.Fuel economy

Reduction of fuel consumption in pulverizerd boiler (2 – 6%), grate boiler (3 – 10%) and gas up to 3%. Savings, savings, savings!!!.

Increasing efficiency

By reducing fuel consumption, the combustion catalyst directly affects the efficiency of the boiler and this parameter is of the greatest importance in modern power boilers.

Internal surface

Keeping the internal surfaces clean is one of the main parameters in maintaining the boiler efficiency at the same high level in the long term.

Emission

Reducing exhaust emissions is one of the most important problems in the world today. The use of combustion catalysts significantly reduces the emission of carbon monoxide CO to the atmosphere as a result of complete combustion.

Stable work

In power boilers, stable operation of the left and right side of the boiler affects the efficiency of the power installation and is desirable by the boiler operator.

Complete combustion

The use of a catalyst results in a more complete combustion of the fuel, which makes it possible to burn coal with a lower calorific value in many installations.

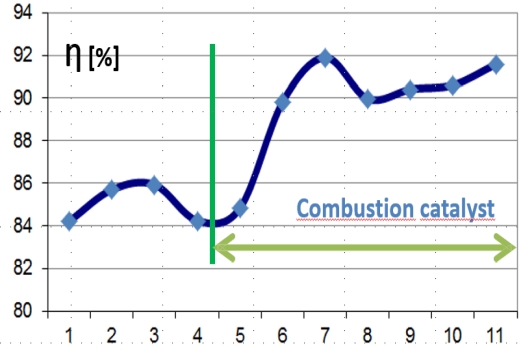

Gas boiler efficiency

In this particular case, the effect of the combustion catalyst on improving the efficiency of a natural gas-fired boiler can be observed. With natural gas fuel, the improvement of boiler efficiency by about 2% is a great achievement. On pulverized coal boilers we achieve an efficiency improvement of up to 6% and on grate boilers up to 10%.

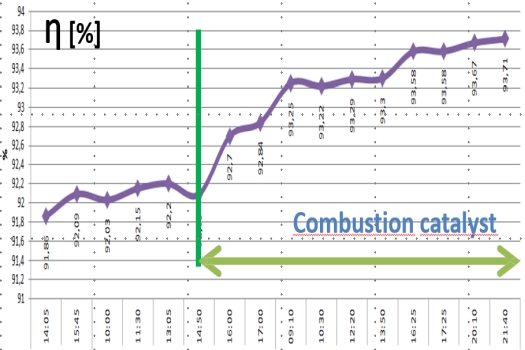

Pulverized coal-fired boiler efficiency

in the case of pulverized coal boilers, the combustion catalyst is dosed to the fuel-air mixture, which results in an increase in boiler efficiency, as in the case of the diagram. Of course, the improvement in efficiency is closely related to the reduction of fuel consumption, complete combustion and acceleration of the combustion reaction.

Maintaining the internal heating surfaces in good condition for a longer period of boiler operation improves year-round efficiency. Proper heat reception by heating surfaces is a key element in power plants and heating plants, as well as in boilers operating seasonally in an uninterrupted period, such as sugar factories.

Complete combustion process

Complete combustion improves efficiency and increases the efficiency of heating devices, the reduction of the amount of carbon monoxide CO is visible in all implementations on power boilers. The catalytic converter also has the effect of changing the combustion rate, which is the main factor affecting complete combustion.

Get in Touch with Us

Our Headquarter is in Poland

Muscari Consulting Sp. z o.o.

Aleja Jana Pawła II 27

00-867 Warszawa, Poland

Phone: (+48) 667 500 501

Email: info@reduxco.com

International partners

Contact us or our partner

Phone: (+48) 667 500 501

Email: info@reduxco.com